https://blog.seneca.it/wp-content/uploads/2022/06/edge_scaled.jpg

https://blog.seneca.it/wp-content/uploads/2022/06/edge_scaled.jpg

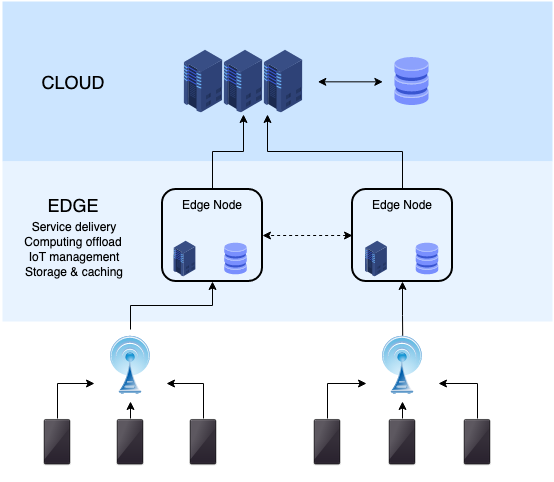

Edge computing refers to a distributed processing model conducted close to the geographic location of the data collection and analysis center, avoiding the use of a centralized server or cloud. The improved infrastructure uses sensors to collect data, while edge servers securely process the data on-site in real time.

Edge computing is essential right now because it presents an opportunity to improve business operational efficiency, increase performance, and ensure data security. Edge technology is also relevant as it is enhanced by new technologies such as 5G, Digital Twin and Cloud-native platforms for applications, databases and systems integration.

According to IDC forecasts, the global Edge computing market will reach $250 billion by 2024, with a compound annual growth rate of 12.5 percent.

Today, Edge technology makes it possible to process large volumes of data where it is generated (directly on the device or in servers nearby), reducing data processing time, the bandwidth required to transfer it, making it unnecessary – in some cases – to transfer the information to the Cloud, while increasing security, operational efficiency and availability of business-critical operations.

Beyond Edge concept (edge of the network) the new paradigm involves the concept of “Edge devices” (any data-generating device at the edge of the network) and “Edge gateways” (used as transition nodes between the IoT and a core network).

Some predict that Edge Computing will bring about the end of Cloud Computing or data centers.

Ultimately, it is not surprising that Edge Computing is considered one of the “revolutionary” new technologies that can change organizations that want to break free from the previous limitations of traditional cloud platforms.

IIoT Edge Solution

Seneca’s new R-PASS modules (shallow versions of the IoT Edge “Z-PASS” modules) offer client/server connectivity solutions for realizing systems of different complexity and with different simultaneous access points to the plant or single machine, also strong in the support of numerous communication protocols such as Modbus TCP-IP Server/Client, Modbus RTU Master/Slave, Meterbus master, SNMP, S7 Client, OPC UA Server, FTP/FTPs Client, FTP/sFTP Server, HTTP/HTTPS server, SMTPs client, Samba, J1939, Canopen.

Equipped with 2 Fast Ethernet ports, 2 serial ports, 2 USB ports, and 1 CAN port, the devices are expandable with the R-COMM communication module equipped with 4G LTE worldwide modem and have 10 I/O channels (4 digital inputs, 4 digital outputs, 2 analog inputs 0..30 V/ 0..25 mA) on board that are expandable.

Integrated into the LET’S remote maintenance platform, R-PASSes can support Point-To-Point connections for Teleassistance or Single LAN for Telecontrol. Through the use of IIoT protocols (MQTT(s), https, http post, OPC UA), R-PASSs also integrate seamlessly with data analysis, supervision and enterprise management, ERP and MES systems. They can also take advantage of the HMI SSD (Surprirse Smart Display) GUI to manage alarms, send commands, set parameters, and display graphs from HTML5 web browsers.

Edge Gateways

Available in versions with and without Wi-Fi and with 2 or 4 Ethernet ports, R-PASS Edge Gateways establish two-way communication between the field and supervision, as well as offering diagnostic, processing also with if-then-else logic) and data storage capabilities to provide services with secure VPN connections and to manage field devices in real time. R-PASSs extend the reach of networks and enable the passing of process data between different layers of IT and industrial communication architecture.

Applications thus range from M2M/IoT communications to remote maintenance, from network integration to protocol conversion to integration with Cloud platforms and services, in most industries.

Edge Controllers

R-PASS with Straton IEC 61131-3 softPLCs also perform tasks as high-performance multifunction controllers that combine PLC functionality with advanced routing and remote access.

They are in fact based on StratON softPLC with integrated web server capabilities and can be expanded with R-COMM 4G/LTE communication modules.

Support for the http post, MQTT(s) and OPC protocols makes these Edge devices true IIoT controllers, which system integrators and machine builders can leverage to quickly derive data from machines and plants communicating via industrial Ethernet or fieldbus, and then relay that data back to IT/IIoT systems easily and securely.

Through these open standards, R-PASS controllers enable the integration and analysis of data from machines, plants, and installations to improve productivity, sustainability, and decision making.

Edge Energy Controller

For Energy Management applications, Seneca offers different types of R-PASS Edge Controllers with support for IEC 60870-101/104 and IEC 61850 communication protocols used for monitoring and remote control of substations and electrical transformer substations.

These units can be used as redundant controllers for plant automation, produced energy management, renewable energy plant management (biomass, photovoltaic, wind, etc.), smart grid development, etc. They can also be configured as web servers and TCP-IP nodes and integrated with Scada, EMS and Web supervision platforms