https://blog.seneca.it/wp-content/uploads/2020/04/m-bus.jpg

https://blog.seneca.it/wp-content/uploads/2020/04/m-bus.jpg

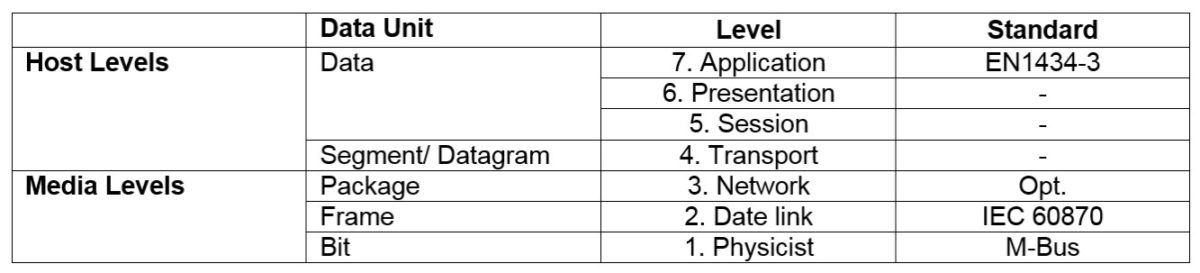

Meter-Bus or M-Bus is a European standard (EN 13757-2 for the physical and connection level, EN 13757-3 for the application level) for the remote reading of water, gas and electricity measurements. M-Bus is a standard that can also be used for other types of consumption.

The interface is made for twisted pair communication for cost effectiveness. The radio variant of M-Bus (M-Bus wireless, M-Bus wireless) is described in the specifications of EN 13757-4.

The M-Bus protocol was developed to meet the need for a remote meter reading system, e.g. to measure gas or water consumptioni. This bus meets the special requirements of battery-powered or remote systems. When queried, the meters must provide the collected data to a common master, such as a laptop computer, which requires the data at periodic intervals to read all the meters in a building.

M-Bus is based on a twisted and shielded twisted pair connection. The speeds are very low in order to cover long distances: the speeds normally used are 300 bps and 2400 bps.

The bus is powered by the master which, by imposing a voltage of between -12Vdc and +35Vdc at the ends of the two wires, supplies the communication interface of the devices: each slave has a specific absorption of 1.5mA. Therefore the master is sized to supply a certain number of devices at maximum.

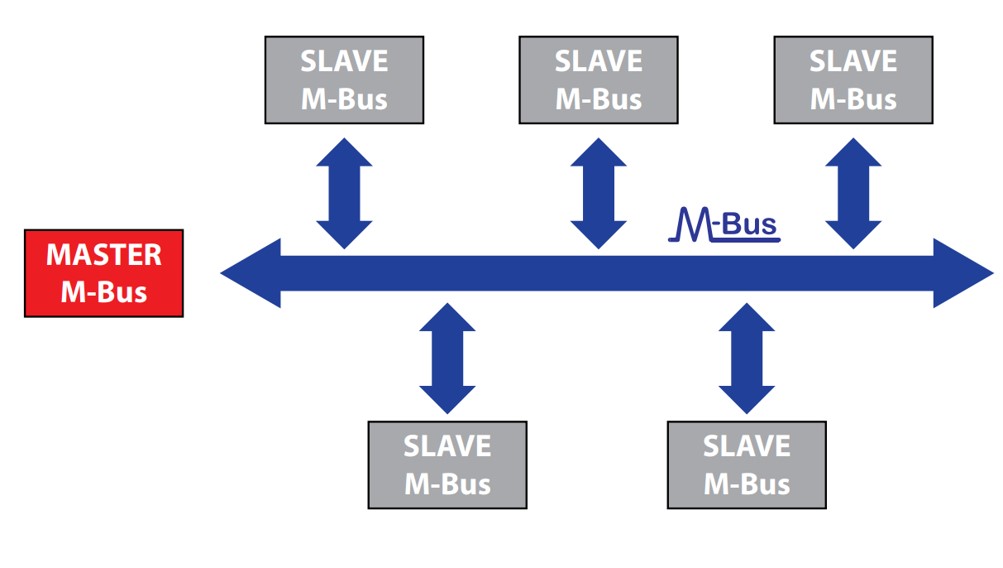

Master-Slave Architecture

M-Bus belongs to the fieldbus family, consisting of information transmission systems based on a common transmission medium to which devices capable of receiving and transmitting information are connected. The information is encoded in digital form and transmitted in the form of data telegrams in serial mode. The transmission mode is asynchronous, half-duplex, controlled by the Master device. The transmission medium consists of a simple two-conductor cable on which all devices are connected in parallel. M-Bus is an open system: technical specifications and communication protocol are publicly available. Thanks to this, M-Bus devices from different manufacturers can be connected and exchanged on the M-Bus network. M-Bus is a master-slave system; communication is controlled by a single device (master) that cyclically interrogates the other devices (slaves) to collect information. A slave cannot take the initiative to communicate, but must wait for the interrogation made by the master. In addition to the data concentrator function, the Master generally offers additional functions such as data storage (datalogger) and remote control via communication interface.

Advantages

M-Bus has been developed specifically for the application of centralisation of consumption data and meter operating parameters and offers a number of important strengths:

- high security in data transmission;

- low wiring costs;

- support long distances without signal amplifiers;

- high number of devices that can be centralized;

- support different connection topologies: star, shaft, linear;

- automatic recognition of connected devices;

- maximum flexibility for combining other I/O and interfaces;

- multiple modules can be used for large amounts of data.

SENECA M-BUS solutions

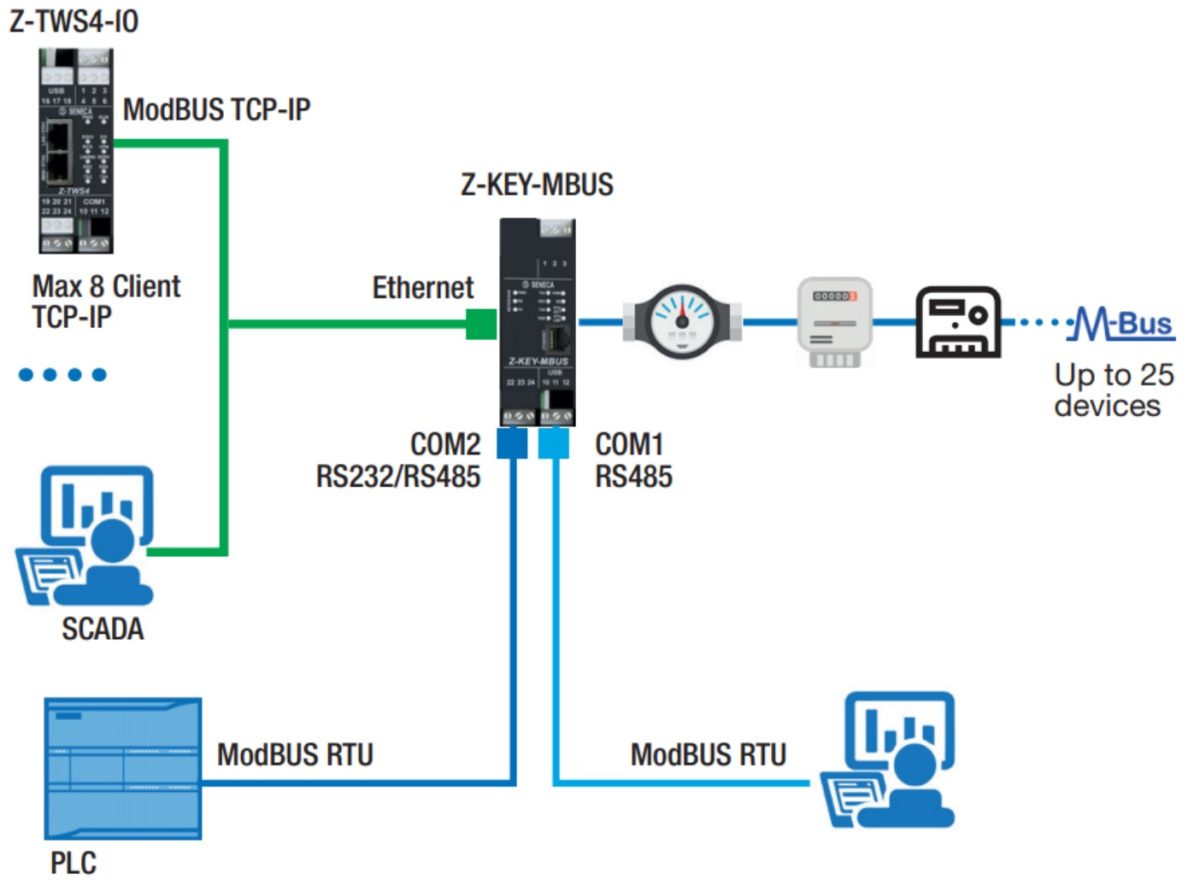

The SENECA Z-TWS4, Z-PASS2-S, S6001-RTU controllers and the S500 Series energy meters open up the field of metering and remote measurement. They can in fact support M-Bus networks through Z-MBUS adapter connected to the serial port COM1 – RS232 or through Z-KEY-MBUS gateway is able to read, convert and transfer data of up to 24 M-BUS instruments.

The management of M-Bus devices through tools integrated in the web server configuration, scanning, diagnostics and appropriate function blocks IEC 61131 Straton read / write. M-Bus (Meter Bus) is the main bus used energy metering and intelligent meter management for separate recording of heat, water, electricity and gas consumption as well as sensors and actuators.