https://blog.seneca.it/wp-content/uploads/2021/05/Seneca-Iskra.jpg

https://blog.seneca.it/wp-content/uploads/2021/05/Seneca-Iskra.jpg

PQMs (Power Quality Meters) belong to the T&M (Test&Measurement) sector. This is the most fragmented instrumentation sector of all. Test&Measurement includes oscilloscopes, analyzers, meters, multimeters, calibrators, signal generators, test benches, probes, and test sensors, whose application cuts across all industries.

In such a crowded market, the numerous suppliers seek to dominate the field in terms of quality, durability, reliability, distribution capillarity and technological innovations. According to analysts, it will be the partnerships between big players, the development of communication networks, the spread of 5G and IoT technologies that will guide the new generation of these tools and its market.

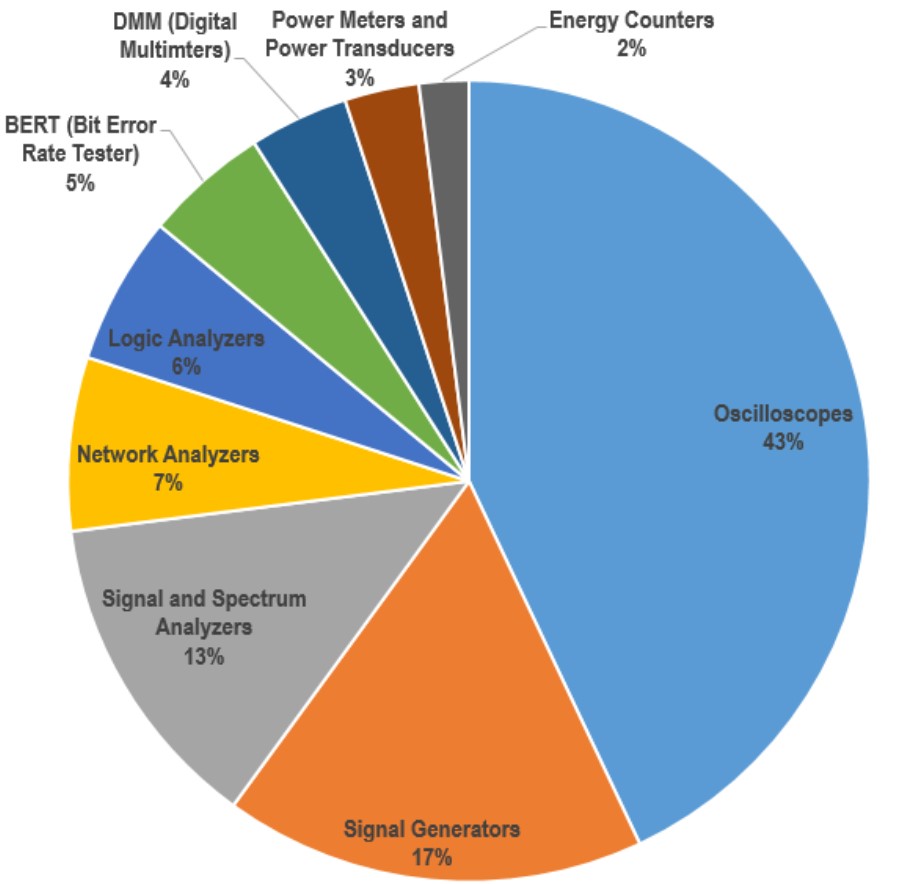

Globally, T&M (Test&Measurement) is worth about 25 billion dollars and an estimated growth rate over the next 5 years (2020-2025) between 4 and 6%. The pie chart below, also derived by induction from aggregate data, shows the segmentation for which the PQM share is worth roughly $1.2 billion.

The concept of “Power Quality

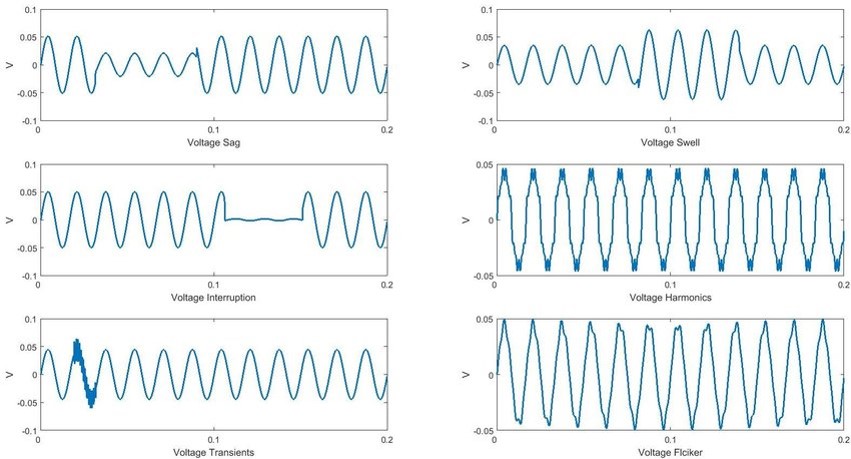

Power Quality refers to the quality of voltage and current, i.e. the extent to which these two quantities deviate from the ideal waveform in terms of frequency, amplitude or phase. The expression Power Quality also refers to a complex system of activities that involve the iteration between an electrical system (usually in the hands of the supplier) and the loads (in the hands of the customer/user) that receive electrical power. The operation of the load is affected by the quality of the power supplied, but in turn the load can generate disturbances directed toward the system.

The causes of disturbances are typically due to voltage amplitude deviation (caused by the variation in active and reactive power absorbed by loads, the action of variable ratio transformers under load, or the connection of capacitive or inductive loads) and frequency deviation (caused by the presence of nonlinear loads and saturating transformers). Insufficient Power Quality measures can result in damage to machinery (electric motors overheating), production non-compliance (machines not working at design conditions), production interruptions, increased energy costs.

Measurement campaign

Having said this, it is good to verify the presence of disturbances and evaluate their entity through a measurement campaign in which the measures must be performed during the operation of the loads, protracted for a significant period of time (at least one week) and concern voltage (frequency, amplitude, phase/neutral voltage, dips), harmonics (THD calculation), current (phase current measurements). Limits and parameters of the measurement campaign are defined by the EN 50160 standard. For each quantity, thresholds must be defined beyond which it is necessary to intervene. For example, voltage variations should not exceed 10% of the nominal value, the unbalance between phases should be less than 3%, the THD should not exceed 5%. Measurements must necessarily be made using equipment that meets the standards, in particular EN 50160. In this sense, PQMs analyze the quality of the energy supplied and the loads connected, safeguard the equipment connected to the network, provide useful reports to keep consumption and anomalies under control, as well as being able to be produced as an element of verification or dispute against the network manager.

In all sectors, from mechanics to data centers, from electronics to medical, where there are equipments or machineries that can suffer serious failures or downtime, as a consequence of voltage dips, flicker, imbalance between phases, a PQM is used to analyze in detail what and when the problem occurred on the power line and to intervene towards the distributor of the service or on its own plant.

SENECA and ISKRA, strategic partners in the name of energy efficiency

SENECA (leading manufacturer of interfaces for automation) and ISKRA (internationally recognized supplier of advanced electrotechnical products) activate a strategic partnership for the range of Power Quality Meters, devices for continuous monitoring of energy quality.

To complete the offer of its production, particularly in the field of energy efficiency and energy management, SENECA becomes the exclusive distributor for the Italian market of iMC784 and MC784 families.

Compliant with EN61000-4-30 and EN50160 standards, iMC784 and MC784 are high performance systems that can be used as stand-alone devices for monitoring and verifying the correct balance of the phases of the plant and for the detection and analysis of disturbances on local networks, transients, alarms and periodic measurements.

Key Features of the iMC784 and MC784 Families

The iMC784 and MC784 provide power quality assessment (according to EN 50160) with automatic report generation. With a frequency range of 16Hz to 400Hz and Class A accuracy (0.1%) in accordance with EN61000-4-30 Ed. 3, the PQMs provide instant evaluation of over 700 electrical measurement values including PQ-related parameters: harmonics (Voltage/Current THD, TDD up to 63rd voltage (PP, PN), current harmonics and inter-harmonics. PQMs can automatically select the range of 4 current and 4 voltage channels (max 12.5A and 1000Vrms) with 32 kHz sampling rate. As “recorders” the systems can acquire waveforms and transients with up to 625 samples/cycle; winds, noise and trend and Power Quality (PQ); a wide variety of data (8Gbytes) in internal memory; faults and PQ reports according to EN50160. iMC784 and MC784 allow 4 quadrant energy measurement + 8 programmable counters with 0.2S class accuracy. iMC784 and MC784 support Ethernet, USB 2.0 Modbus, DNP3, FTP, MQTT, GPS and IRIG-B communication for real time clock synchronization.