https://blog.seneca.it/wp-content/uploads/2021/03/daq-banner-1.jpg

https://blog.seneca.it/wp-content/uploads/2021/03/daq-banner-1.jpg

Data is the new oil and the linchpin of business strategies. Today, with the ongoing digital transformation, traditional data collection systems are merging with solutions based on the new digital models of sharing. The combined use of acquisition, test and measurement instrumentation proves to be a fundamental lever to implement an effective diagnostic, maintenance and testing strategy, as well as general process optimization (reduction of waste and non-conforming products, increase in efficiency and productivity, etc.).

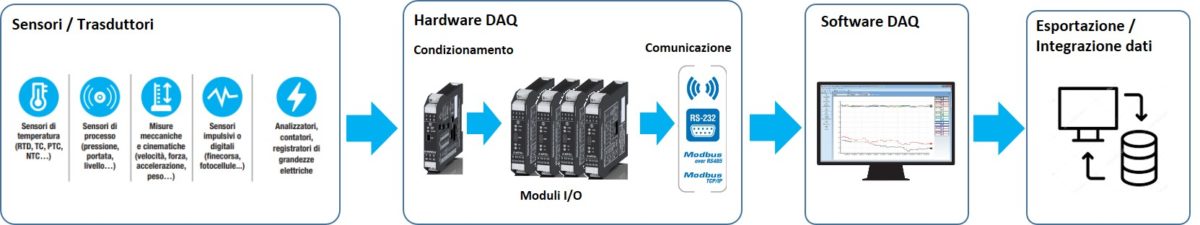

Data acquisition systems, often as DAQ or DAQ (Data AcQuisition System) allow monitoring the process to be controlled, verify the compliance with validation and production control procedures, improve customer service (certified products), support management systems (quality, energy, environment, safety).

Data acquisition options

Modern DAQ (Data Acquisition) systems must combine the traditional industrial requirements (real-time control, remote signal distribution, ease of deployment, scalability, availability, reduced implementation and maintenance costs) with the new 4.0 features: virtualization on cloud, BYOD (Bring Your Own Device) multi-device access, management of large historical and real-time volumes on a Business Intelligence basis, integration with EDI (Electronic Data Interchange) and Supply Chain management systems, IoT and Big Data.

From the point of view of peripheral hardware, there are several main options for the acquisition of I/O signals from the field. The first is PC acquisition cards of multifunction, PCMCIA and external types. Generally, the performances are reduced in comparison with the analogous architectures PCI, PCI Express, ISA, PC/104, ISA to advantage of the compactness of the module and the measurement performances.

Another option is given by the acquisition modules housed in special racks. These systems allow to increase the performance of the measurement system, as they are designed to optimize the environment inside the instrument.

Another option is distributed or remote I/O systems. This approach involves distributing the measurement hardware in different modules housed near the measurement points and connected by Fieldbus or a communication network.

We should also not forget the huge amount and extreme variability of use and components of “open” technologies such as Arduino and Raspberry pi, increasingly used in data acquisition.

It is also worth mentioning the data collection systems mainly used in the process industry such as recorders and dataloggers characterized by increasing memory capacity, wide measurement range, reduced maintenance and integrated connectivity technologies. Beyond the constraints of hardware are PC-based DAQ analysis and data storage software, and virtual instrumentation, a particularly flexible programming technology with applications involving high-performance inspection, automated testing, quality control, diagnostics and metrology.

Electronic signal processing

In the field of data acquisition, the starting point is “signal conditioning”, i.e. the electronic technology aimed at solving the problems of implementing a common interface between the sensors (or actuators) and the control units, when the output signals from the sensors are not homogeneous in terms of electrical nature (current, voltage, resistance, etc.), level and type (direct voltage, alternating, pulsed, etc.). The signal conditioning stage includes all the electronic circuits that transform the output signals from the transducers into an electrical signal of a homogeneous type. Typical functions of this stage are attenuation of high signals, rectification and levelling of alternating signals, voltage transformation of current signals, elimination of electromagnetic noise superimposed on the useful signal, galvanic isolation of electronic signal processing devices.

In relation to the levels of electrical quantities of signal transmission, there are standardizations for the industrial environment that allow the connection of heterogeneous devices by type and manufacturer. For example, analog signals that travel long distances are normally transmitted with the so-called current loop in the range 4..20 mA. Other standard signal levels, normally used when transmission distances are short (e.g. from the edge of the machine to the control panel), are found in the -10..+10V range for analog signals and in the 0..24 V range for digital signals. The conditioning of analogue signals includes operations of anti-aliasing filtering (passive or active), amplification, attenuation, impedance matching, galvanic isolation, measurement normalizations (in current, voltage, resistance, frequency), excitation with measurements from resistance thermometers, thermocouples, thermistors, strain gauges, etc. Signal conditioning devices (converters) can be located in electrical panels, onboard sensors, actuators or controllers, integrated in A/D conversion boards and in multiplexing systems.

The software solution

Acquisition software applications have largely supplanted local dataloggers and recorders. They are usually supplied with specific DAQ hardware and a set of functions that allow real-time visualization, data storage in standard formats, trend analysis and integration with third-party systems.

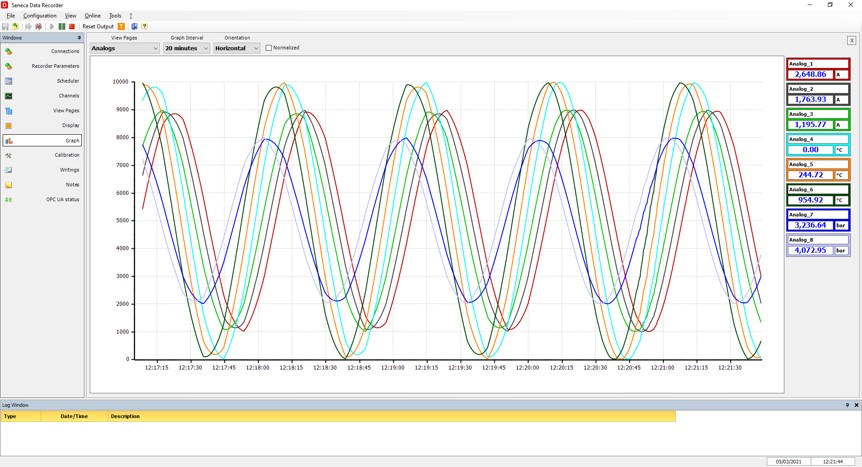

SENECA solution, Data Recorder 2.0, is an open, scalable and cost-effective Windows PC-based software recorder, ideal for professionals, maintainers, students, researchers, designers and technical department managers active in test sessions, measurement and simulation, in test benches, in electronics labs and for teaching, in test rooms, in climatic chambers, in engine rooms, in industrial ovens, in environmental and energy measurements and in-plant verifications.

The physical data acquisition is done by distributed I/O modules of SENECA Z-PC Series (with or without CPU), and in general by any standard ModBUS RTU slave device. The communication between hardware and PC can be serial (RS232/RS485/ModBUS RTU) or Ethernet / ModBUS TCP, on wired or wireless physical medium. The normalized graphic representation can be set up with nibs or display (digits). The real-time display offers multiple selection possibilities: channel groups, representation interval, scroll direction on screen. The historical archive (data and alarms) can also be consulted using a special viewing tool (Trend Viewer).

The export and exchange of purchase data, as well as in .csv format (manageable with Microsoft Excel), can take place with standard SQLite and OPC Server technologies suitable for integration with Scada, management systems, automation devices, databases and cloud platforms. Data Recorder assures also advanced functions of alarm management (with implementation of digital outputs), report management (with trigger events) and mathematical elaborations with algebraic, linear, trigonometric, boolean functions (digital channels), averages calculation, compensations and deviations on measures.

Data Recorder 2.0 is free to download, upon registration, with a full, unlimited license for up to 2 channels. For more information and pricing about extended licenses, please visit www.seneca.it/data-recorder .