https://blog.seneca.it/wp-content/uploads/2020/03/ES00-1.jpg

https://blog.seneca.it/wp-content/uploads/2020/03/ES00-1.jpg

Galvanic isolation is a signal conditioning technique that allows the signal to pass from the source to the measuring device via a transformer or optical or capacitive couplers.

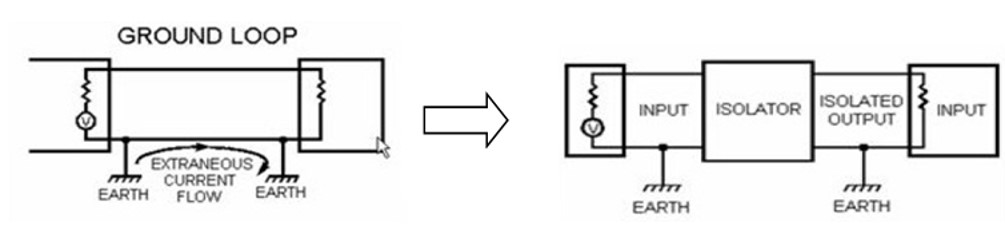

In addition to breaking ground loops (or ground loops), isolation interrupts high voltage peaks and eliminates common mode high voltage, protecting operators and control and measurement devices.

The 2-way isolation galvanically separates signals from each other and decouples measurement circuits. The 3-way isolation decouples the supply voltage to the input/output circuit and allows operation with a single operating voltage.

Passive isolation is used when no additional voltage supply is required. The isolator module is supplied via the input circuit and is transmitted to the output. This loop supply is characterized by low power consumption.

In industrial environments the isolator is typically placed between a transmitter (e.g. sensor) and a receiver to galvanically isolate signals, between a PLC and an inverter, or between I/O channels of a controller.

There are therefore at least 10 technical reasons to introduce a galvanic isolation stage upstream of the acquisition and control system:

- Removing noise from the field, in order to avoid alterations due to different potential differences, i.e. the so-called ground loop effect (several ground connections can cause problems). Each loop is linked to a different potential and this (potential) difference creates flow currents between the earths that add to the signals. The use of the galvanic isolator eliminates this type of noise.

- Separation of signal and power supply circuits, so that each circuit operates autonomously from the point of view of signal acquisition and management.

- Reliability in signal transmission, ensured by minimizing errors and disturbances.

- Transmission security, as the high isolation protects the electronics

- Coverage of distance between field and control greater than 20 meters, ensured by the conversion of the signal in µA (less sensitive to noise).

- Protection against high ground potentials.

- Immunity to electromagnetic interference.

- Signal and power wiring in the same duct, to minimize the effect of the magnetic field.

- Transducer power supply. Thanks to the galvanic isolator, it is also possible to provide power to the sensor and resolve any power supply conflicts on the same loop.

- Protection of control units. Normally PLC isolated boards are much more expensive and with lower protection levels than the single dedicated isolators.