https://blog.seneca.it/wp-content/uploads/2024/03/industria-4.0_2.jpg

https://blog.seneca.it/wp-content/uploads/2024/03/industria-4.0_2.jpg

The question arises: how does Industry 5.0 come about and why is it being talked about since Industry 4.0 is not yet fully implemented? This is actually a rather common objection. We should not look at Industry 5.0 as another industrial revolution in the strict sense, rather as a course correction, an attempt to overcome the limitations of Industry 4.0. The underlying theme is to put the individual, the environment and society as a whole at the center of the new digital transformation inside and outside factories. After all, this need stems from practical considerations. Just as Industry 4.0 was a response of European industry to the global crisis of 2008, a political-technological plan to modernize factories, so the Industry 5.0 model is fueled by the need to put humans back at the center, to make them protagonists, not subordinate to technology or unprepared to manage it. With different motivations, Japanese institutions have noticed and started talking about it since 2016 with the concept of Society 5.0. In the mid-1910s, several scholars in Northeastern Europe were the first to explicitly talk about Industry 5.0 putting emphasis on green issues and the circular economy.

In the United States influential entrepreneurs such as Tesla’s Elon Musk and Salesforce’s Mark Benioff have evoked a fifth industrial revolution to address excessive automation and digitization applied without ethical guidance and social meaning. In 2020, the European Union with its document “Industry 5.0 – Towards a sustainable, human-centric and resilient European industry” offered a clearer direction to this paradigm.

The differences

Global consulting firm Frost & Sullivan has identified five key changes in the transition from Industry 4.0 and Industry 5.0: customer experience, hyper-customization, responsive and distributed supply chain, interactive products, and return of labor to factories. In particular, Manufacturing 4.0 is characterized by mass customization and smart products, while with Industry 5.0, customization with “human touch,” creativity, and interactive products will be key players. Also central is the concept of the factory: intelligent in 4.0 (smart factory), cooperative in 5.0 (collaborative industry). Then there is the issue of training and work organization: the remote component is strong in both models, but in 5.0 the human presence takes on a strengthened value. Also not to be overlooked is the energy scenario, which is decidedly more oriented toward bioeconomic models, renewable energy and energy efficiency with Industry 5.0

Technologies

The enabling technologies are basically the same as those of Industry 4.0 (IoT, Cloud, Big Data, Additive Manufacturing, Augmented Reality, Digital Twin, etc.), although Artificial Intelligence, Collaborative Robotics and human-machine interface characterize more the 5.0 model. But playing a key role in the transition from 4.0 to 5.0 are mainly the so-called transitional technologies. Largely based on machine learning and software engineering (cognitive agent systems, semantic web, autonomous intelligence) and partly based on the convergence of interdisciplinary subjects (evergetics, problem solving, game theory, learning strategies). These disciplines are the most scientifically interesting part of Industry 5.0 and should be the accelerators of this technological transition, although it is too early now to assess their full potential, especially in a socioeconomic framework characterized by many uncertainties.

Watch the video “Industry 5.0. A Guide to the Fifth Industrial Revolution and the 5.0 Transition Plan – Part One”

Duration: 14.36″

Summary

How Industry 4.0 was born

How Industry 5.0 was born

The characteristics of Industry 5.0

Advanced models, technologies and applications

Production, training and labor

The Italian Transition 5.0 Plan

Although related and often used synonymously, these are two different concepts. Industry 5.0 is an industrial transformation and business model in which man and machine cooperate with the ultimate goal of providing added value to production while respecting the ecosystem, consumer needs and social welfare.

Transition 5.0 is a tax incentive plan put in place by the Italian government to facilitate digital transformation and energy savings starting in 2024.

How to access the Italian Transition 5.0 Plan.

As with the Transition 4.0 Plan, the tax incentive for Transition 5.0 is available to all companies operating in the country, without distinction regarding company size, legal form or sector. The only access requirement is the implementation of innovation projects aimed at reducing energy consumption.

Enterprises in a state of voluntary liquidation, bankruptcy, compulsory liquidation and composition with creditors are excluded from the benefit. Also excluded are companies subject to prohibitory sanctions under Legislative Decree No. 231 of June 8, 2001.

To qualify for the tax credit, investment projects must include the purchase of new tangible and intangible assets that are:

instrumental to the business operation referred to in Annexes A and B annexed to Law No. 232 of December 11, 2016;

interconnected to the company’s production management system or supply network;

aimed at a reduction in the energy consumption of the production structure of not less than 3 percent or, alternatively, at least a 5 percent reduction in the energy consumption of the processes involved in the investment.

Incentives

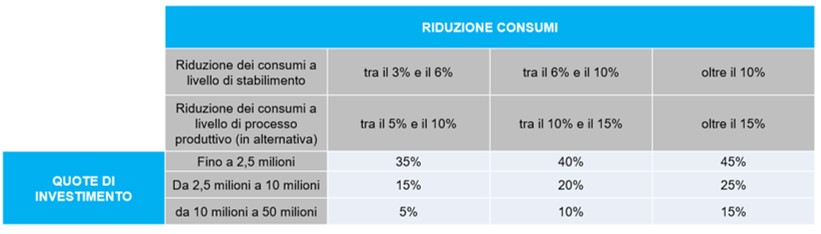

The incentive is recognized in the form of a tax credit with the application of a variable rate based on the amount of the investment and the share of energy savings achieved.

For investments up to 2.5 million from 35 percent to 45 percent

for investments between 2.5 and 10 million from 15% to 25%

For investments between 10 and 50 million from 5% to 15%.

Watch the video “Industry 5.0. A Guide to the Fifth Industrial Revolution and the 5.0 Transition Plan – Part Two”

Duration: 14’40”

Summary:

Plan Transition 5.0 the incentives

Transition 5.0 Plan: the certifications

The SENECA Proposal