https://blog.seneca.it/wp-content/uploads/2026/02/robotic-arms-modern-factory-setting_23-2151977854.avif

https://blog.seneca.it/wp-content/uploads/2026/02/robotic-arms-modern-factory-setting_23-2151977854.avif

In the industrial world, we have been talking about Industry 4.0 for years, but the real turning point is not the cloud or AI: it is the way in which the machine produces and distributes data. From IT-OT convergence to smart junction boxes, automation is moving from closed systems to replicable platforms.

***

When isolation becomes the problem: why connectivity is not enough

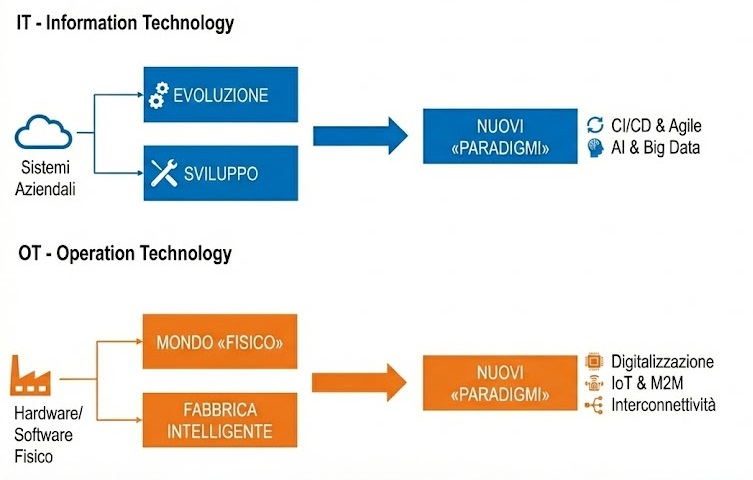

For decades, industrial machines have lived in splendid isolation. A PLC, an I/O network, a fieldbus, an operator panel: everything worked perfectly, everything remained local. IT managed management systems, OT controlled production processes. Two parallel universes, with incompatible languages, priorities and timing.

Then came digitization. And it has not limited itself to connecting machines to the network: it has highlighted a structural problem that the manufacturing industry has always carried with it.

When we talk about Industry 4.0, the first reflex is to think of communication protocols, gateways, cloud platforms. In reality, the real crux of the matter is another: each machine is born as a unique project. Different protocols, different logics, different data structures, different interfaces. It works perfectly in the workshop, it works at the customer, but it doesn’t scale.

Plant builders know the result well: every new installation starts all over again. Digitization, instead of becoming an efficiency multiplier, turns into a recurring cost. It is not a technical problem: it is an economic problem.

The modern factory produces a huge amount of data, but the machine is not designed to produce information. There is a fundamental difference: the electrical signal from a sensor is not yet usable information. For it to become so, you need architecture.

IT and OT, two worlds compared

From signal to common language: the Smart Junction Box as a modeling point

Industrial data always follows the same path: from sensor to control, from control to network, from network to software, from software to decision. So far, each step has spoken a different language. True digitalization is born when this path becomes continuous — not a link, but a chain.

Shifting the focus from “controlling the machine” to “structuring the machine’s information” is the real game-changer. It is no longer a question of adding connectivity to existing systems, but of rethinking the machine as an information infrastructure.

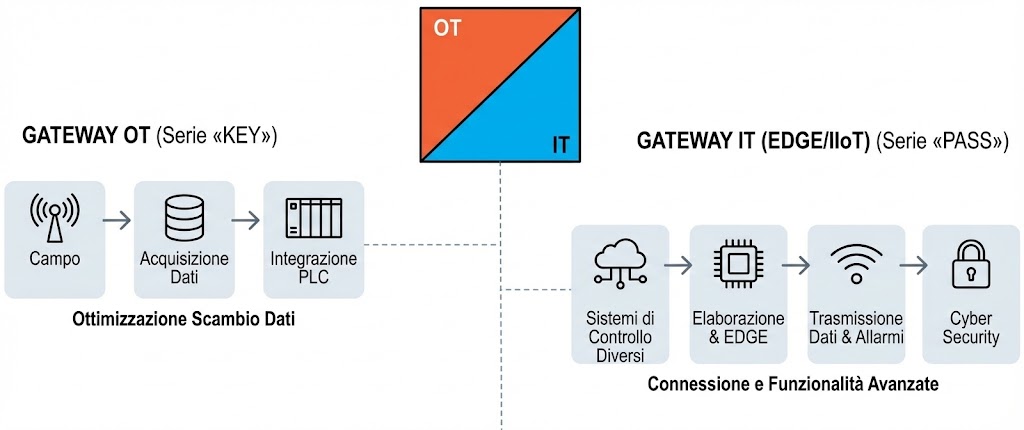

This is where a concept that has undergone a profound evolution comes into play: the gateway. Historically thought of as a protocol adapter, today it becomes something different: the data modeling point.

The Smart Junction Box is not a network accessory. It is the physical and logical place where the machine stops being just hardware and becomes an information system. It collects signals, normalizes them, contextualizes them and distributes them at all levels: control, supervision, analytics, remote services.

In other words, it doesn’t connect systems — it defines a common language.

This radically changes the design approach. The machine is no longer built with a point-to-point integration towards the customer’s system, but designed with a standardized, replicable data architecture that is open to future services.

Seneca DAQ Architecture – Smart Junction Box

Edge computing and standardization: from the machine-project to the machine-platform

For years, integration went through a central computer: SCADA, IPC, local server. But every machine with a PC becomes a point of fragility: updates, maintenance, management of software versions, IT security.

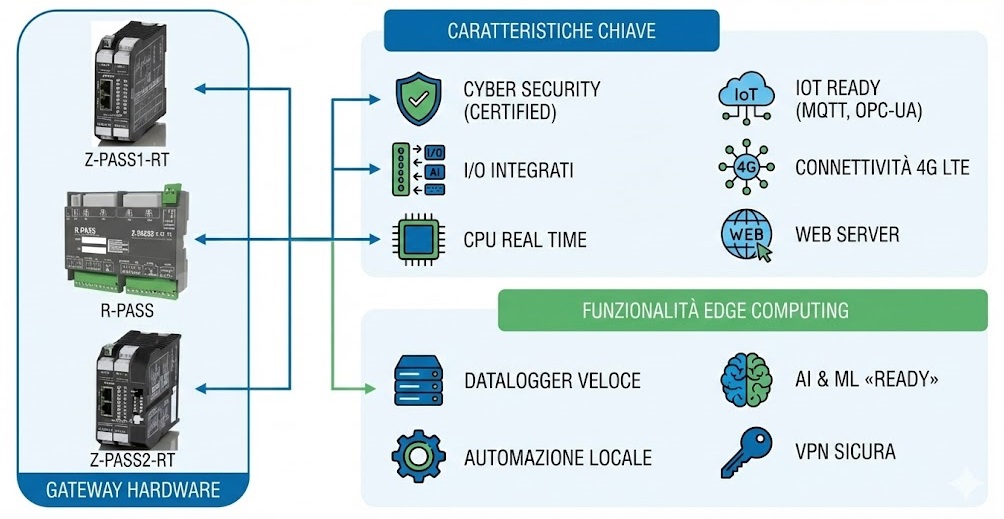

Bringing intelligence closer to the process with edge computing completely changes the model: processing takes place where the data is born.

It’s not just a technical advantage, it’s a change of architecture. The factory no longer depends on a single point where data flows. Each machine becomes autonomous, but at the same time part of a coherent system.

When data is standardized, something new happens: the machine stops being an isolated project and becomes a platform. Same architecture in all customers. Same services that can be activated. Same remote maintenance. Same evolution over time.

It is no longer a delivery. It’s a life cycle.

This has concrete consequences: reduction of integration costs, possibility of offering recurring services, ability to evolve the machine even years after installation. The manufacturer is changing from a system supplier to a service provider.

SJB Ecosystem “PASS” Series: Hardware, Connectivity and Intelligence at the service of Industrial IoT and Edge Computing.”

The third level: from traditional automation to continuity management

Traditional automation stopped at testing. The new automation starts after start-up. Because value is not just producing parts, but maintaining constant performance, analyzing abnormal events, preventing failures, updating features.

To do this, you need a foundation: a stable and permanent data infrastructure. The Smart Junction Box fulfils exactly this role: it transforms the machine from a controlled device into an operating node in the digital factory.

For years, IT-OT convergence has been talked about as an integration between business departments. In reality, a third level is emerging: the information infrastructure of the machine.

It does not replace the PLC, it does not replace the management software. It makes them consistent over time. It creates the necessary bridge so that real-time control and business management can finally communicate without forced mediation.

When every machine speaks the same language, something unexpected happens: the factory is no longer a collection of isolated plants, but a network of operational nodes. It is no longer a question of monitoring, it is a matter of making coherent systems communicate.

And this is where automation changes its nature: from process control to continuity management.

Many digital projects fail because they start only from software or only from hardware and do not consider both parties.

Transformation, on the other hand, starts from the structure of the data. First you define how the machine communicates, then you decide what to do with it. Order is fundamental: without architecture, every service remains an experiment.

Industry 4.0 was not the introduction of the cloud, nor the arrival of artificial intelligence. It was the discovery that the machine must also be designed to exist in digital time.

The real innovation is not to connect a machine, but to build it so that it remains connectable. When this happens, the machine is no longer an island. It becomes part of the factory’s information infrastructure.