https://blog.seneca.it/wp-content/uploads/2025/12/predictive.png

https://blog.seneca.it/wp-content/uploads/2025/12/predictive.png

The management of energy consumption is today a strategic variable for industrial competitiveness. The partnership between SENECA and STUPIRE responds to this need with an integrated solution for monitoring and predictive control of consumption, capable of correlating field data, energy prices and production costs. A data-driven approach that enables more informed operational decisions, improves energy efficiency and generates measurable economic returns.

***

Strengthened by over ten years of experience in the world of industrial automation and energy monitoring, SENECA offers hardware solutions designed to reliably bring field data to supervision systems and digital platforms. Gateways, network analyzers, and I/O modules form the technological foundation on which open and scalable IIoT architectures are grafted, which are increasingly required in today’s complex production environments.

STUPIRE supports this infrastructure with system integration and software development skills, oriented towards advanced supervision, data analysis and operational decision support. The collaboration between the two companies stems from the desire to go beyond a purely descriptive approach to the monitoring of consumption, building a solution capable of linking energy measures, production dynamics and economic variables.

The application context is that of a large manufacturing group specialized in the design and production of plastic components for the Food & Beverage and Beauty & Home sectors. A production system divided into several plants, characterized by dozens of highly automated molding lines, annual volumes of the order of billions of pieces and an industrial infrastructure already oriented to the paradigms of Industry 4.0, with MES, automated logistics and advanced quality control.

In such an environment, energy is a critical variable in production cost: presses, auxiliaries, plant utilities and support systems generate high and distributed consumption, which requires a timely and process-related view. In this scenario, the partnership takes on a strategic value: the data acquisition infrastructure provided by SENECA guarantees a widespread and reliable collection of measurements on the machine, while the applications developed by STUPIRE transform energy data into operational and economic indicators useful for production management. The result is an integrated solution that supports concrete paths of efficiency, sustainability and cost control.

Starting from the field measurements of the individual plant users, the system allows you to acquire full awareness of energy consumption and how it impacts production costs

Problem and solution

The main problem lies in the poor correlation between real energy consumption, production costs and the price of energy. Without timely monitoring on board the machine and without predictive analysis tools, energy remains a “suffered” cost item, analyzed only a posteriori through the bill. This approach does not allow either to optimize the scheduling of processes, or to correctly assess the impact of contractual choices or investments in self-production from renewable sources.

SENECA R203 three-phase network analyzer used for the measurement and acquisition of electricity consumption on the machine, with integration of energy data into supervision and predictive control systems.

The solution developed by STUPIRE in collaboration with SENECA is based on an integrated field and cloud architecture. On the hardware side, the system uses SENECA R-PASS-W-4-0 industrial gateways, R203 network analyzers and Z-PC series I/O modules, for a total of about 200 measurements managed between electrical quantities and process signals. Communication takes place via Modbus TCP/IP and RTU at the field level, with data publication via MQTT to the cloud portal.

Field-cloud architecture with SENECA R-PASS gateway: data acquisition via Modbus from R203 and Z-PC I/O, EDGE processing and MQTT publication to the cloud.

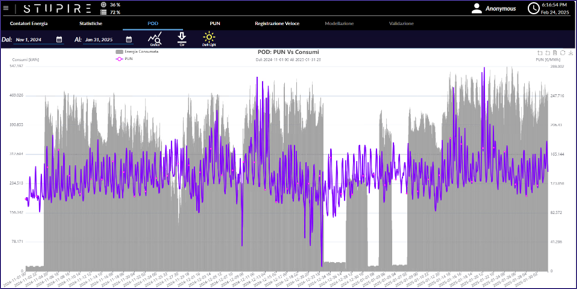

On the software level, STUPIRE has developed vertical applications that transform the raw data into value information: from the monitoring of consumption by individual user, to the integration of the PUN (Single National Price) for the analysis and historicization of the cost of energy, up to the comparison with the POD data of the bill. Advanced functions such as the Energy Supervisor allow predictive control of production costs, while the Energy Footprint modules allow you to calculate the real energy mix and the carbon footprint of the processes, even in the presence of photovoltaic systems.

POD application. Monitoring the absorption profile in combination with the PUN above allows you to verify the cost of the energy quota reported in the bill.

Benefits and prospects

The economic benefits of the solution are measured on several levels. In terms of ROI, the reduction in energy costs derives both from the optimization of production scheduling according to the price of energy, and from the identification of waste and anomalies at the level of individual machines. The most significant KPIs include the energy cost per unit produced, the specific consumption per line or order, the degree of self-consumption from renewable sources and the reduction of CO₂ emissions associated with the processes. The availability of historical and comparable data over time also makes it possible to support strategic decisions on supply contracts and energy investments.

The SENECA-STUPIRE partnership demonstrates how the integration of reliable industrial hardware and advanced application software can transform energy from a simple cost to a competitive lever. Predictive consumption control is a key element of the digitalization and sustainability paths, in line with the principles of Industry 4.0 and 5.0. Future prospects include the extension of predictive logics through advanced analysis algorithms and integration with MES and ERP systems, for an increasingly synergistic management between production, energy and sustainability.