https://blog.seneca.it/wp-content/uploads/2023/09/current-1.jpg

https://blog.seneca.it/wp-content/uploads/2023/09/current-1.jpg

In industrial electrical measurement practice, they are the first link in the measurement chain. Low-voltage (B.T.) current transformers (or transducers) or ammeters enable the exact value of the current applied to the primary to be traced by measuring the secondary current. They are used from the simplest applications with analog indicators, to the most complex where transducers, energy meters or multifunction instruments are involved, and finally in monitoring systems.

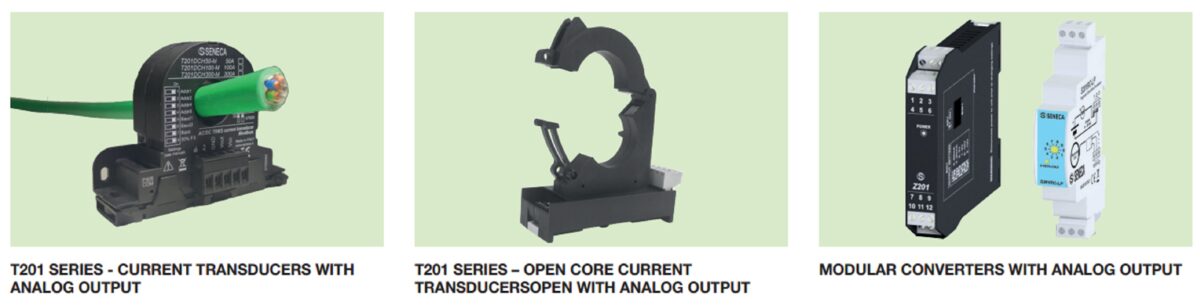

Current transducers with analog output

Current transducers with output in volts or milliAmperes (also available with power from measurement loops, ModBUS interface and digital contacts to handle alarms) provide current measurements that can be directly acquired by PLCs, indicators and acquisition and control systems, without the interposition of separate transducers and without wiring for auxiliary power. The measurement conversion stage and output signal generation is integrated within the transducer. Modular panel-mounted current converters measure alternating current applied at the input or acquired through sensors and then provide standard mA or V signals directly proportional to the measured current.

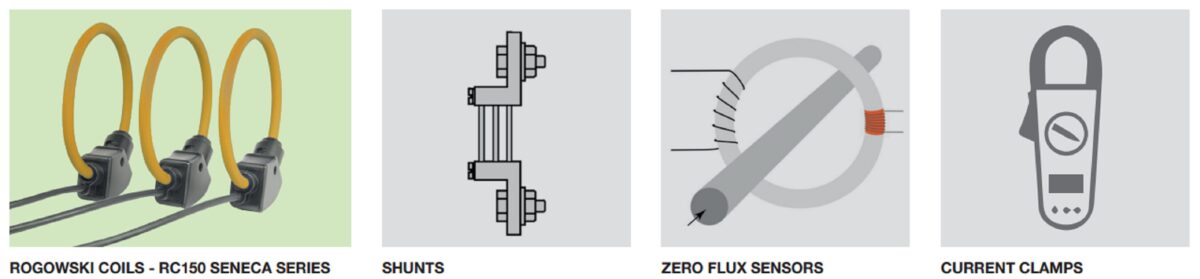

Current sensors and measuring instruments

Rogowski sensors are flexible coils without a magnetic core placed around the current conductor. They are suitable for making high current measurements by winding large bundles of cables, bus bars, irregularly shaped conductors and difficult access. Current shunts detect current flow through a precision low ohmic value resistor inserted in the current path. Zero Flux current sensors use a winding that makes them ideal for high-precision measurements. Also available are ammeters, current clamps, and multimeters that allow current to be measured quickly with diagnostic functions and without circuit interruptions.

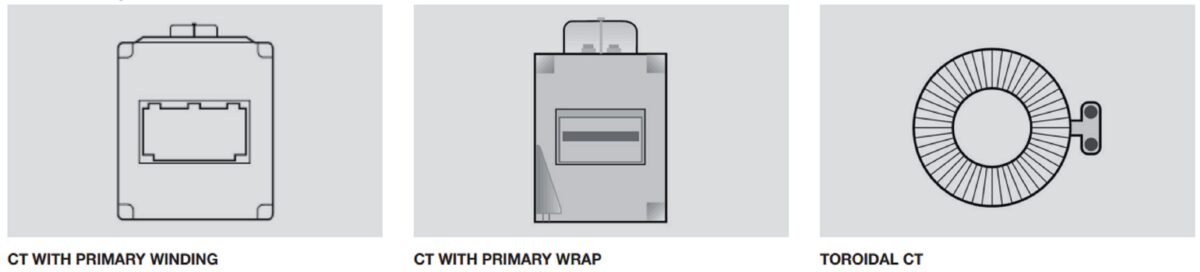

Current meter transformers (CTs)

Ammeter transformers or CTs consist of two windings insulated from each other and a magnetic core. The primary winding is passed through by the current to be measured, while the secondary winding supplies the measuring instruments. CTs are characterized by the transformation ratio between the primary and secondary current. They can be primary-through (hollow or busbar) to reduce the primary current to a secondary value of a few amperes, primary-wound (with low primary values or with high power associated with small CT size), toroidal CTs in which the conductor passes through the central hole and on the core are wound coils.

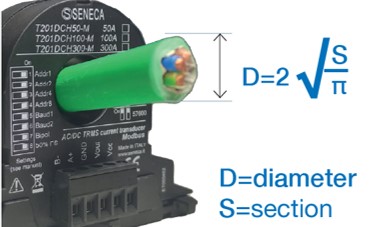

Current transducers – cable sizing

For the determination of current carrying capacity and cable installation method, reference is made to IEC 60364-5-52, which considers the reference conductor temperature to be 70°C and the ambient temperature to be 30°C. However, it should be noted that the determination of the sizing of cables and insulated bars (section, thickness, diameter, length) in relation to the intensity of the current flowing through them must be related to various parameters and criteria such as the heat balance, insulations, feeds, materials, voltage drop and power loss of each specific installation. However, the data must be interpreted and contextualized in the context of electrical design, wiring and analysis of the electrical characteristics of the devices and components used.

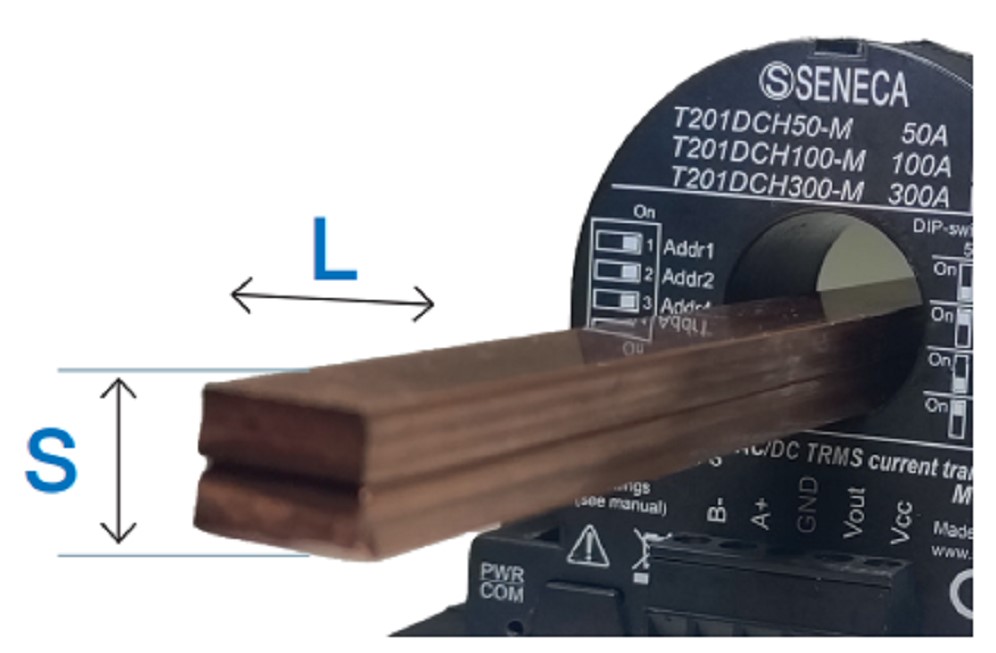

Current transducers – insulated busbars.

Solid Copper Bars are used in electrical panels, for power distributions and when predefined connection, branch and attachment points are not available. Solid Copper Bars with rounded edges are excellent electrical conductors and are valued for their ductility, strength and durability. In addition to switchboards, they are used for distribution or transportation of electricity, in the production of blinds, electrical conduits and power supply lines in industrial electrical installation with typical thicknesses of4, 5, 10 mm and lengths of 1750 and 4200 mm.

For more information on sizing and selection of SENECA current transducers, please refer to this document.